Cost-Effective Prototype / Low Volume Molding

Undercuts and complex areas usually requiring slider or up and aways, can be achieved using "knock-out" inserts and manually dismantled.

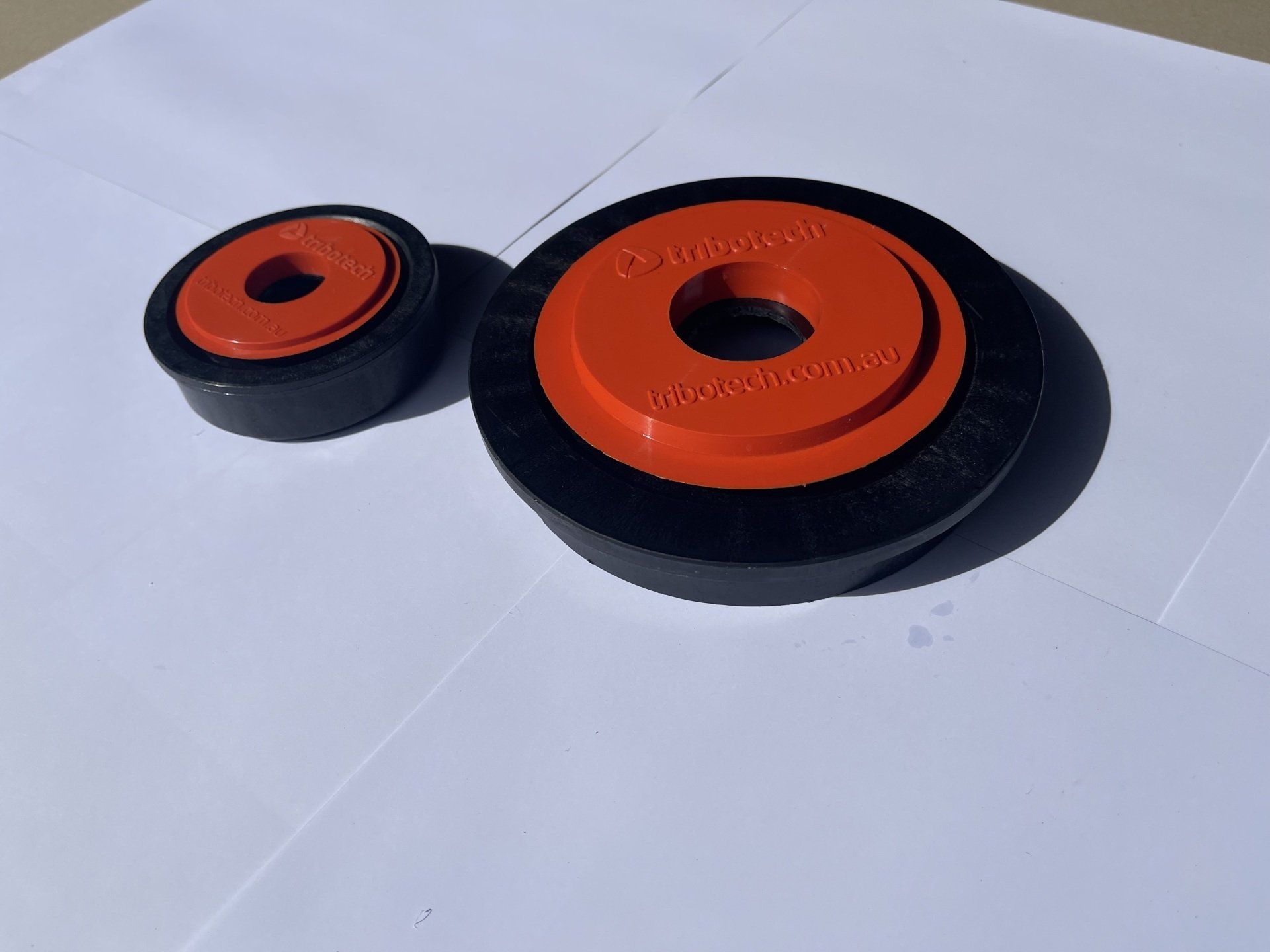

Loading in inserts, over-molding, or custom components that require encapsulation can all be achieved.

The parts themselves can be trimmed or post-worked, to enable machining of undercuts or features that would have made the tooling price prohibitive.

This enables you to get fully functional parts in the correct material to test or trial so your confidence in the production tool can be assured.

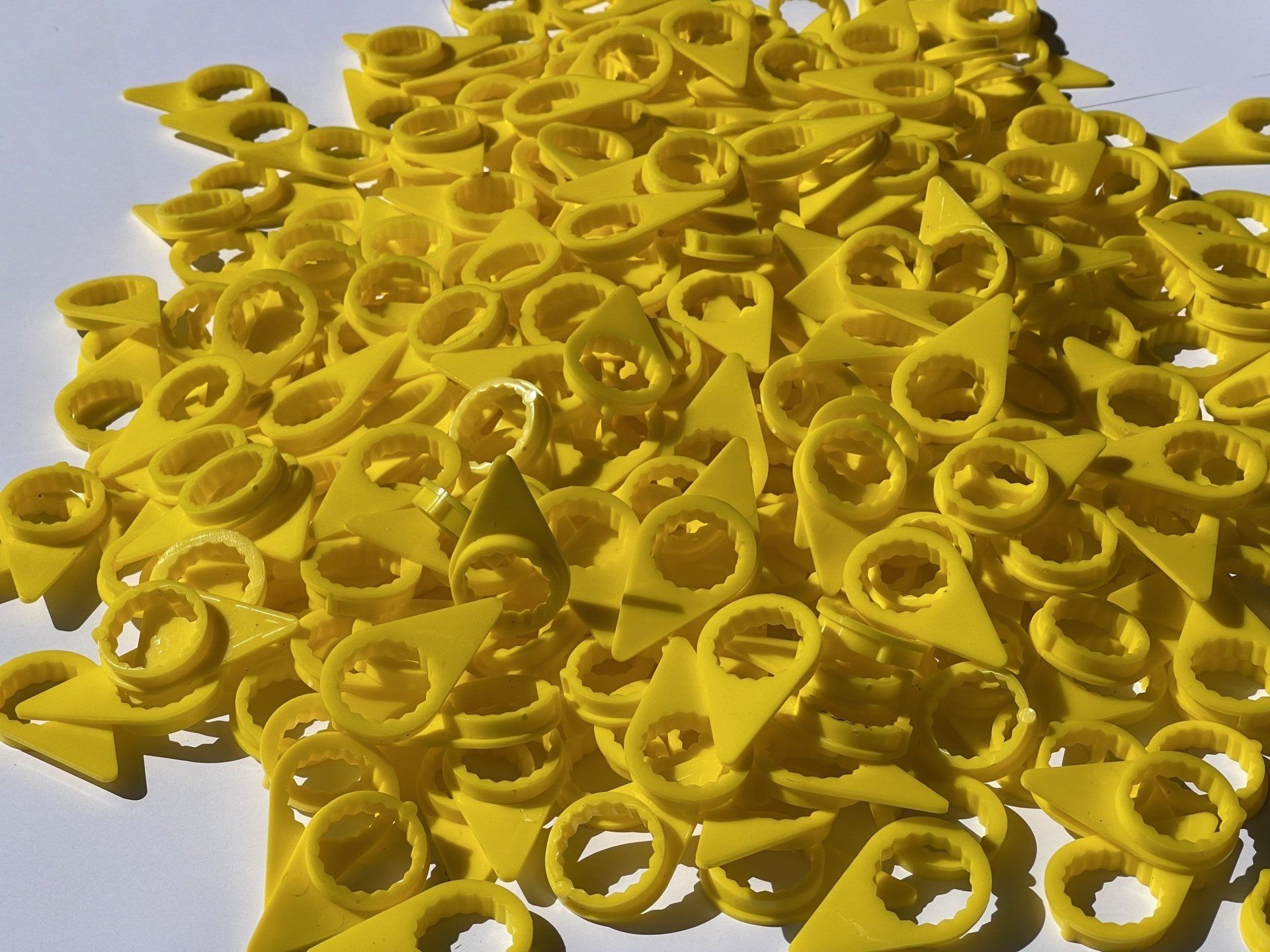

Prototype Moulding: from 1 to 100’s

Low-Med Volume Moulding: From 1 to 1000’s

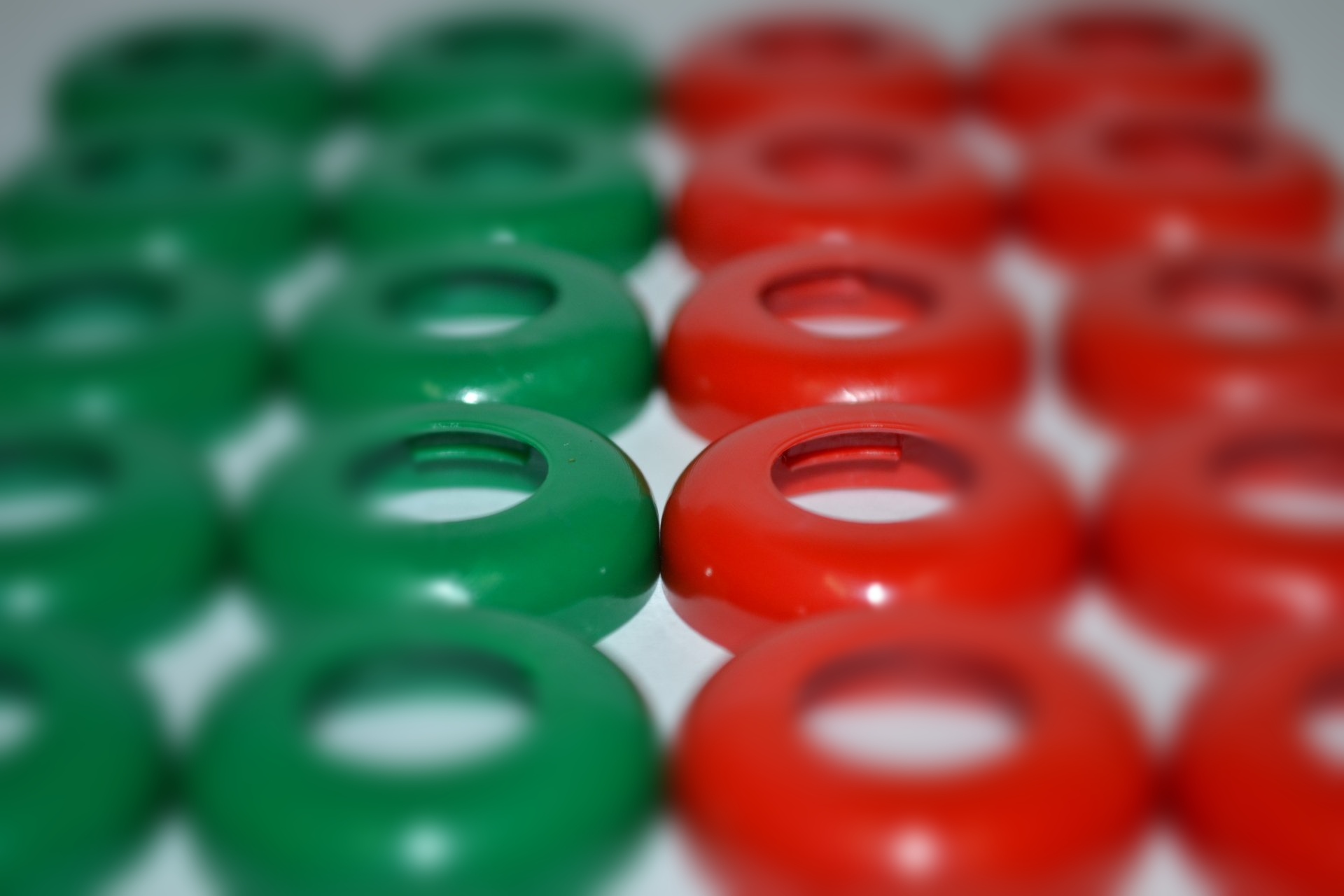

Production Moulding

Moulding Machine 35T

Moulding Machine 55T

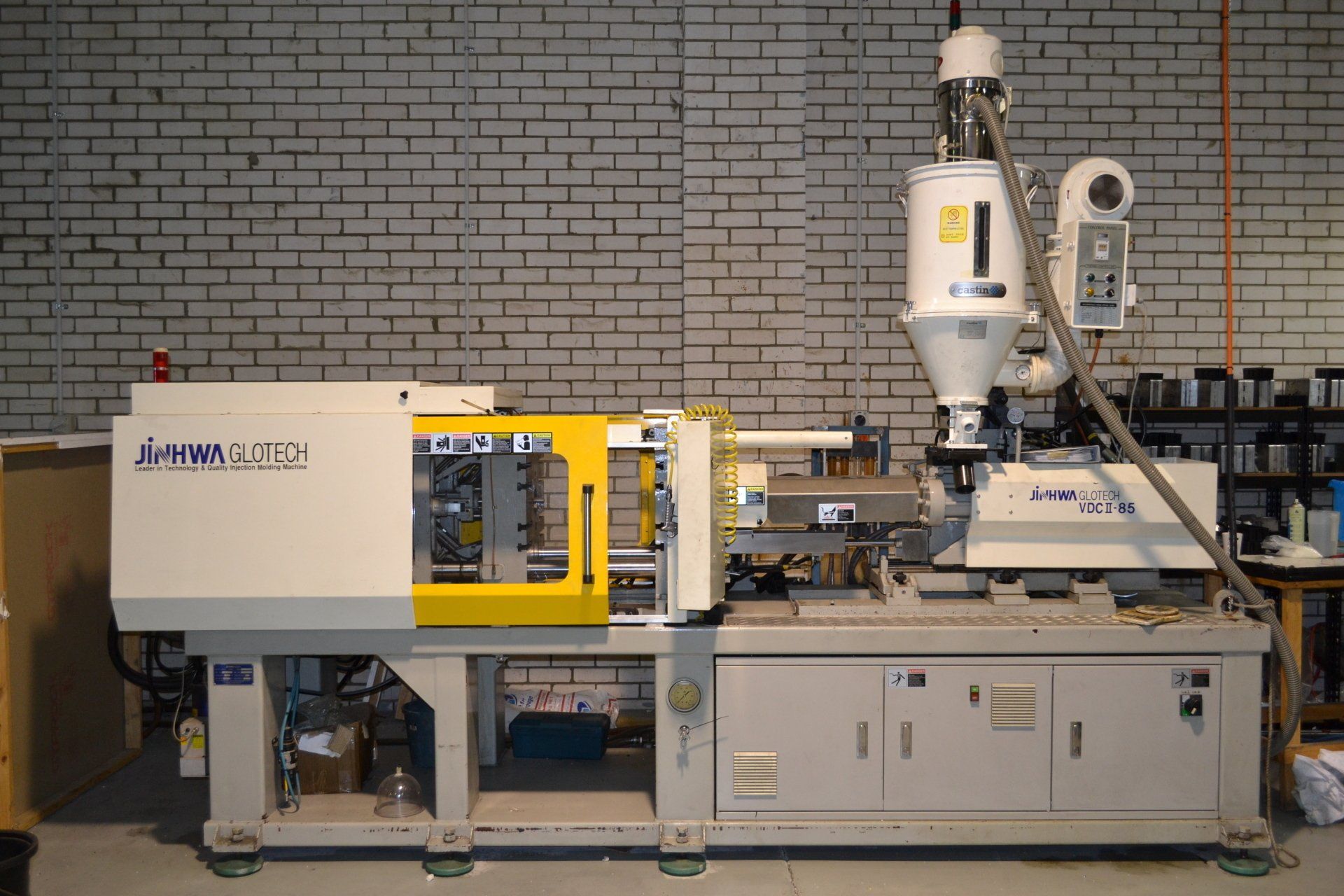

Moulding Machine 85T

Moulding Machine 180T

Molding Machine 180T INJECTION UNIT

Shot weight: 351 - 598g

Clamping force: 180 t

Space between tie bars: 505 × 500

Max Tool Height: 720 mm

Moulding Machine 328T

Molding Machine 328T INJECTION UNIT

Shot weight: 1200g

Clamping force: 328 t

Space between tie bars: 505 × 500

Max Tool Height: 720 mm